Precision Measuring Capabilities

An executive from a large faucet manufacturer asked us, “How do YOU control your quality?”

When we first started supplying custom molded seals and gaskets, we realized that in order to assure our customers they were getting the product they ordered, we had to be able to measure and control quality on every part we sell at Satori Seal. We perform a secondary inspection at our facility in Rancho Cucamonga, CA on all parts in addition to the factory’s inspection.

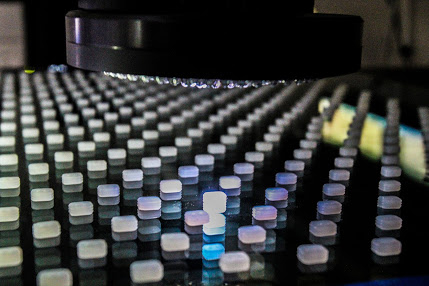

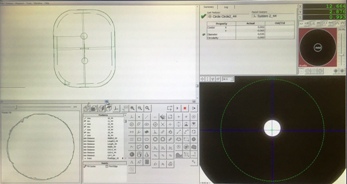

We invested in state of the art Video Measuring Machines (VMM) with the capability of measuring dimensions on parts that would be impossible to measure with traditional handheld devices. Hand held measuring devices such as vernier calipers, pin gauges, and c-calipers were not enough to measure all the critical and complex dimensions on various parts. With the video measuring machine’s capability to write custom programs, we have incorporated these devices into our everyday quality control inspection procedures.

Not only can we measure extremely accurate with the Video Measuring Machine, but its programmable capabilities means we can repeat these measurements over and over. In the picture we are measuring 22 dimensions on 500 parts. Also the VMM, we are able to measure features on parts that can’t be measured by handheld measuring devices.

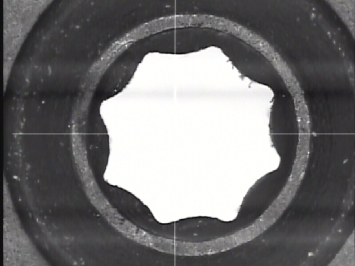

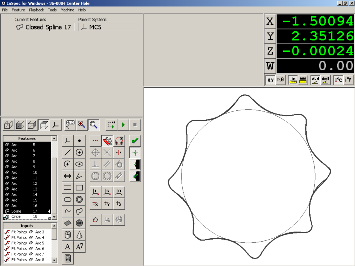

With the VMM Satori Seal is able to accurately measure this 1/16 inch octagonal orifice and accurately calculate the area.

Not only can we measure extremely accurately with the Video Measuring Machine, but its programmable capabilities mean we can incorporate it into our quality inspection procedures. In the picture we are measuring 22 dimensions on 500 parts.

These services are available to Satori customers only.